Ceramic Heaters elements

STANDARD

Ceramic heating elements

Ceramic heating elements are used for the pre-heating, post-heating and stress relieving treatment for joint welding operation.

The modularity of the ceramic beads allows the production of a wide range of heating elements with different shapes and dimensions in order to fit as accurate as possible the different geometries of the pieces which has to be heated.

Ceramic heating elements brochure

Download the product data sheet

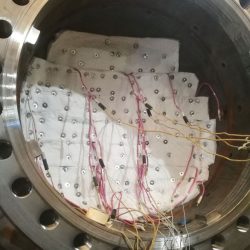

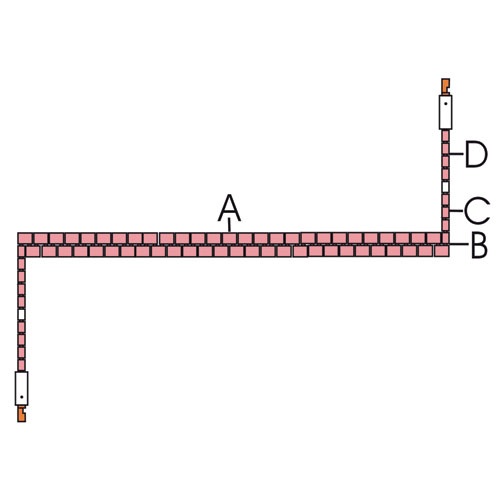

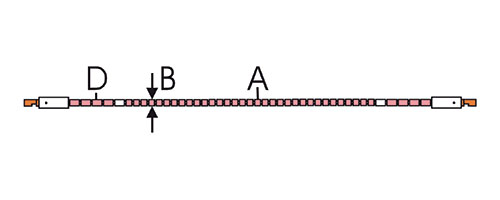

HEATING ELEMENTS STRUCTURE

• Ceramic beads made of alumina 98%

• Heating wire made of Ni/Cr – 80/20

• Max. temperature 1050°C

• Max. electric current flux 50A

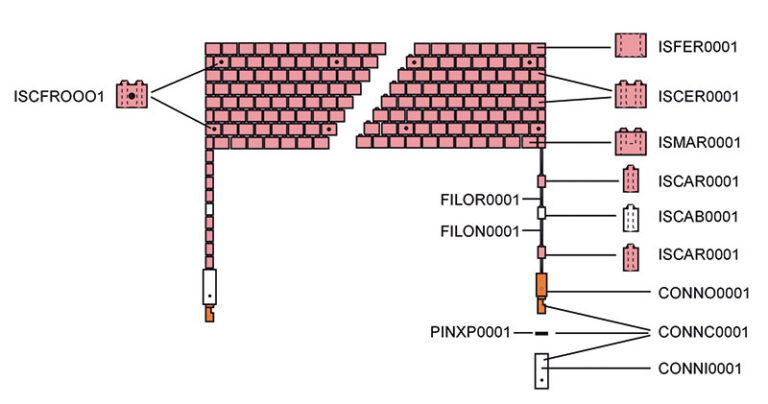

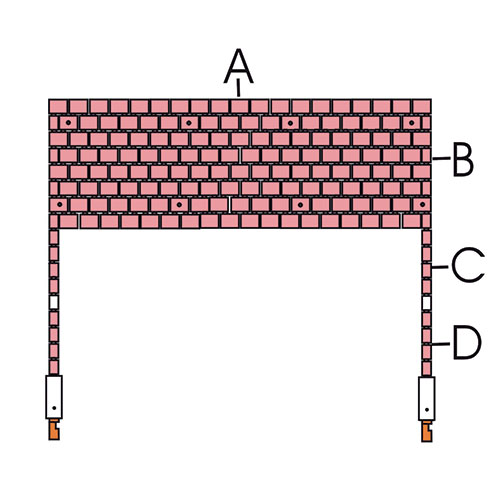

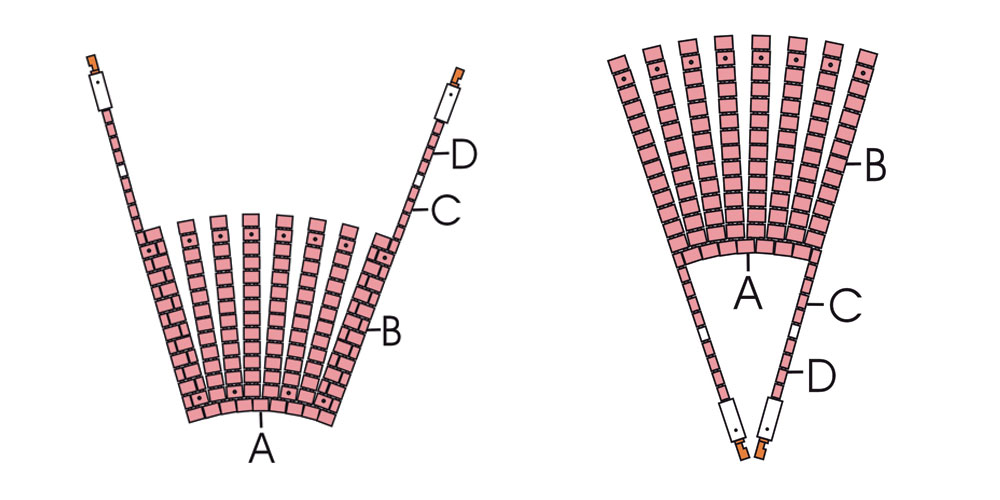

CAPTION

A Flexible side

B Rigid side

C Warm tail

D Cold tail

MAT

A and B with variable length

Code: RSTUS + four-digits progressive number

STRIP

A and B with variable length

Code: RSTRS + four-digits progressive number

FINGERS

A and B with variable length

Code: RDITA + four-digit progressive number (with tails out from open side)

Code: RDICT + four-digit progressive number (with tails out from close side)

Fingers heating elements can be produced with both MAT and STRIP shapes

SNAKE

A = variable length

B = 40mm

Codice: RSNAS + four-digit progressive number

ONE LINE

A = variable length

B = 10mm

Codice: RUNIS + four-digit progressive number

REPAIR CERAMIC BEADS

1 ISTUB0001

Id=9mm | White tube bead L=42mm Od=12mm Id=9mm

2 ISMAR0001/T

Half male end bead pink (pair) with hole

3 ISCFR0001/T

Half main body bead pink (pair) with hol

4 ISFER0001/T

Half femail end bead pink (pair) with hole